We offer a wide range of graphite absorbers which are used in various chemical industries and are in compliance with various Environment Protection Standards and Recovery Benefits. It is manufactured using superior quality material and is durable, highly efficient, thermal shock resistant and corrosion resistant. Available in different models and specifications, it can also be custom designed as per the specifications provided by client Chemical reaction giving out HCL gas are common in chemical industry the absorption of this gas and concentrating it to HCL solution gives benefits of meeting environment protection standards and recovery benefits. But solution of hydrochloric acid in water liberates important quantity of heat (approx 450 k cal / kg of gas absorbed)

Efficiency of hydrochloric acid manufacture is therefore, a function of following three principal factors.

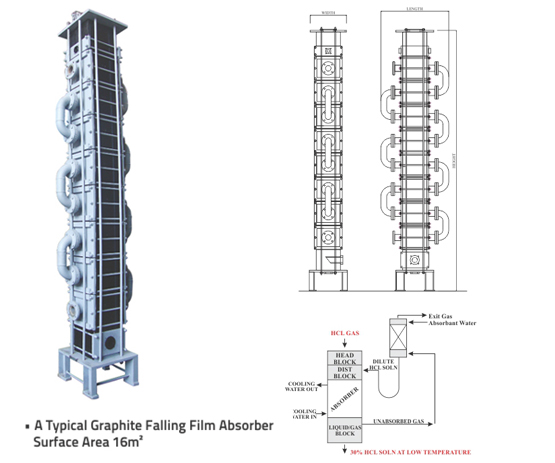

Water to be absorbed is uniformly distributed over the upper face of first process block by a special distributor block provided at the top of the column.

The absorbent descends as thin, absolutely uniform film down the passages of first block and collection the upper surface of the next block where it is again redistributed.

This is repeated at every subsequent block, until the absorbent is discharged through the lower end of the column, this ensures perfect redistribution of the absorbent film at every block interface breaking up therefore breaking of the film (as happens in straight tubular passages) is impossible.

This system ensures perfect distribution and correspondingly provides highest efficiency.

The gas to be absorbed is alternately compressed and expanded and so kept in a highly turbulent state.

Consequently, the gas molecule impinge with great energy on the absorbent film, producing highest absorption efficiency.

Taking full advantage of excellent thermal conductivity of graphite, highest heat exchange efficiency is obtained and reacting fluids in the process passages are maintained at lowest temperature.

Result

By using falling film absorber one can get 30% HCL soln in single pass at low temperature. Achieving absorbed gas efficiency as high as 85% 90% thus minimizing pumping cost, this system is more efficient as compared to H. D. P. E. Packed column.

| Model | Hold Data on Process Side(mm) | Number of Holdes on Process Side | Hold On DIA Service Side(mm) | Number of Holdes on Process Side | Surface Area on Process side(m)block |

|---|---|---|---|---|---|

| GP1 | 18 | 60 | 9 | 105 | 1 |

| GP2 | 18 | 104 | 9 | 162 | 2 |

| GP3 | 18 | 126 | 9 | 210 | 2.85 |

| GP20 | 22 | 86 | 9 | 120 | 2.07 |

| GP30 | 9 | 301 | 9 | 168 | 3 |

| GP35 | 22 | 125 | 9 | 144 | 3.5 |

| GP45 | 9 | 408 | 9 | 216 | 4.5 |

| GP90 | 9 | 650 | 9 | 368 | 9 |