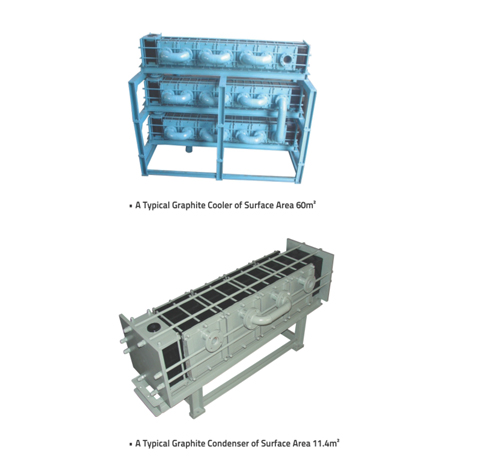

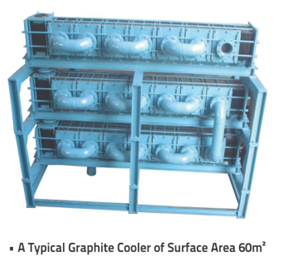

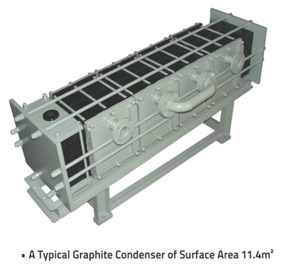

Graphite Heat Exchanger

Graphite coolers or heat exchangers consist of a blocks drilled on two sides . One side of these blocks contains the fluid that must be either heated or cooled. The second side contains coolant or the heating medium so that it can either provide the heat required or absorb the heat from the process media through high thermal conducive Graphite blocks. Block type heat exchangers are typically used for high-pressure This is because the block type heat exchangers are robust due to their shape and strength.

There are several thermal design features that are to be taken into account when selecting coolers or heat exchangers like:

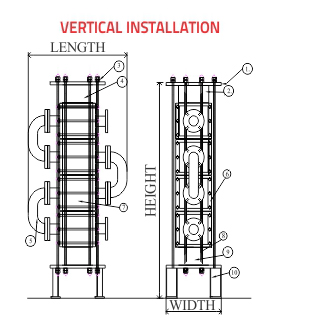

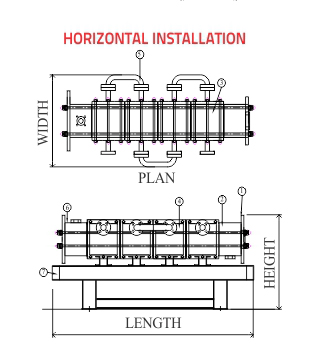

Horizontal designs

Vertical designs

Capable of handling heating utility medium as steam, heat transfer oil or other mediums.

Capable of handling cooling medium as water or even brine.

Multi-Stage Steam Jet Ejectors:

Staging of ejectors becomes necessary for economical operation as the absolute suction pressure decreases. Based upon the use of auxiliary equipment, two and three-stage ejectors can either be condensing or non-condensing types.