For batch plant applications requiring coarse vacuum,low level installation and inline scrubbing.With the liquid recirculating pump being the only moving part the Liquid jet

Exhausters System is simple to maintain and reliable to operate.

The ability to produce vacuam and simultaneously scrub entrained gases before discharge,makes the system ideal for contaminted and/or corrosive applications

Advantages:

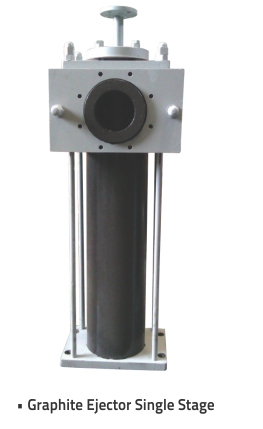

A wide range of graphite ejector offered by us is the combination of water jet ejector and steam jet ejector. These ejectors are acknowledged for handling highly corrosive vapors and fluids and saves energy. These precision engineered ejectors are high in quality, maintenance free and thermal shock resistant. These find their applications in bulk drugs, agrochemicals and allied industries and can also be customized as per the requirements of clients.

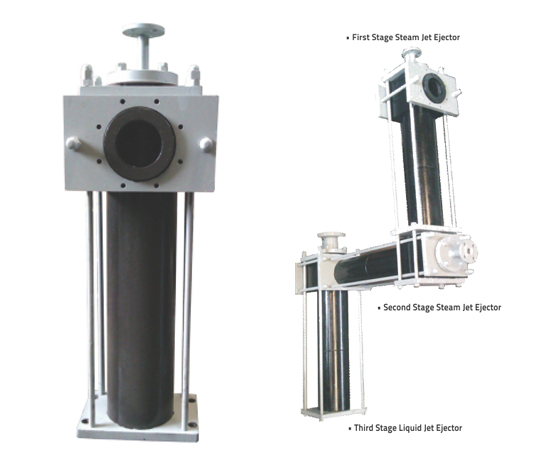

Staging of ejectors becomes necessary for economical operation as the absolute suction pressure decreases. Based upon the use of auxiliary equipment, two and three-stage ejectors can either be condensing or non-condensing types

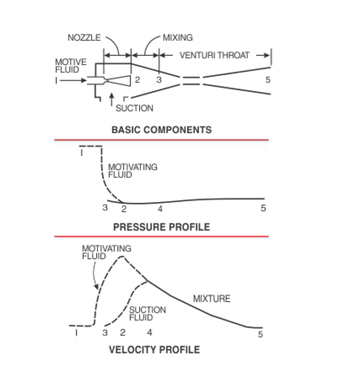

Single-Stage Steam Jet Ejectors are based on the ejector-venturi principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure.

Three basic parts of typical ejector are nozzle, mixing chamber and diffuser. High pressure motivating fluid enters nozzle.

Pressure profile(b) and velocity profile (c) of the fluids are identified by points described by points described above.

In the typical ejector configuration shown, stages are identified by letters assigned in revrse alphabetical order.

As a result the final stage discharging to essentially atmospheric pressure is Z;the penulimate stage is Y.