Our clients can avail from us the precision engineered graphite sulfuric acid dilution unit that is design and developed using superior quality raw material and advanced manufacturing technologies. It is simultaneously beneficial for both dilution as well as cooling of acid. The unit is high in performance and can withstand various adverse working conditions

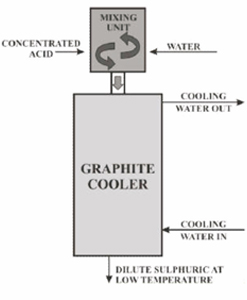

Diluting concentrated sulphuric acid releases, considerable quantities of heat with mixing temperature up to 160°c and above, it is therefore beneficial to dilute and cool acid simultaneously.

This can be accomplished in a single operation with graphite block type dilution cum cooling unit, unit consists of mixing head, which provides separate feed for concentrated sulphuric acid and dilution water. Block type cooling unit provided along with it serves to carry off the heat produced in the course of dilution.

The water and acid are combined only in mixing -chamber, from here dilute acid flows through " process channels of the process blocks, these process channels comes indirectly in contact with the service channels through impermeable graphite and using its high thermal conductivity, as a result desired temperature of dilute acid is obtained at outlet.

| Model | Hold Data on Process Side(mm) | Number of Holdes on Process Side | Hold On DIA Service Side(mm) | Number of Holdes on Process Side | Surface Area on Process side(m)block |

|---|---|---|---|---|---|

| GP1 | 18 | 60 | 9 | 105 | 1 |

| GP2 | 18 | 104 | 9 | 162 | 2 |

| GP3 | 18 | 126 | 9 | 210 | 2.85 |

| GP20 | 22 | 86 | 9 | 120 | 2.07 |

| GP30 | 9 | 301 | 9 | 168 | 3 |

| GP35 | 22 | 125 | 9 | 144 | 3.5 |

| GP45 | 9 | 408 | 9 | 216 | 4.5 |

| GP90 | 9 | 650 | 9 | 368 | 9 |